The permanent solution for food-safe performance.

Minimize the risks of accidental contamination and reduce avoidable stoppages. Permanent lubrication takes the guesswork out of bearing maintenance.

High-pressure washdowns jeopardize bearing grease and seals, increasing the need for frequent lubrication.

What makes greasing a bearing in these environments so challenging?

![]()

- Bearings perform best with an ideal grease fill – yet seals make those quantities impossible to know.

- The greasing process can introduce damaging contaminants.

- Washout of grease during cleanings can leave bearings under-lubricated.

- Lubrication systems may send varying quantities and qualities of grease to each bearing.

Permanent lubrication can make your bearings work more effectively.

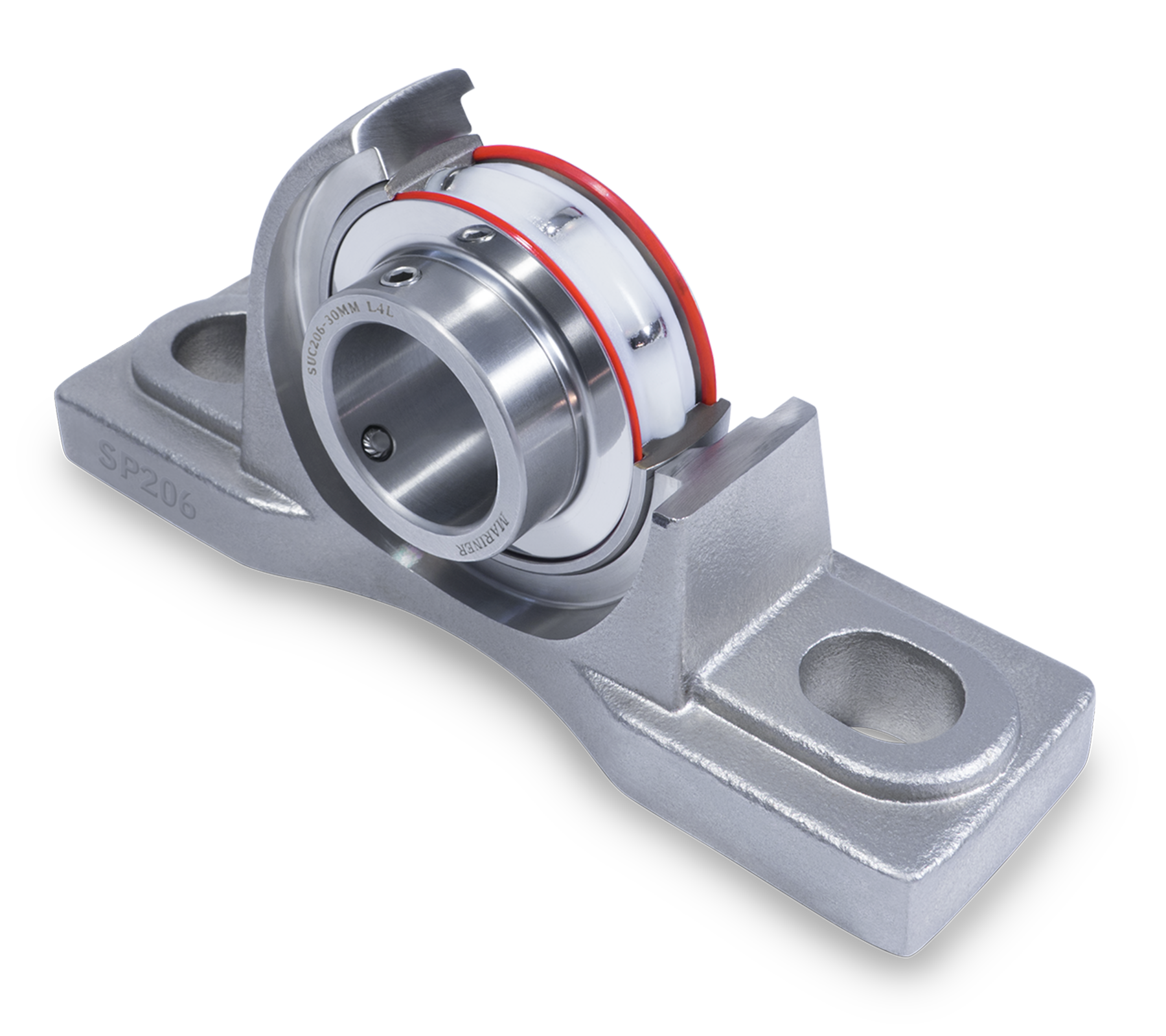

Permanent lubrication is an oil-saturated polymer material molded into the interior of the bearing, filling all internal space without impeding the rolling elements. Micro-pores as small as one ten-thousandth of an inch within the polymer release oil while in use and reabsorb it when the bearing is at rest. Permanent lubrication can hold up to four times the base oil as most greased bearings.

Minimize contamination and reduce stoppages with permanently lubricated bearings.

Permanent lubrication removes the human element, allowing for a more efficient workflow.

Start a chat with us

A permanent solution.

Permanent lubrication isn't just a replacement for grease.

Lubrilife maintains its form during high-pressure washdowns. This lends strength to the bearing seals from the inside out. It also has excellent oil retention. It never leaves bearings under-lubricated and minimizes contamination to surrounding areas.

Introducing

Remove the biggest variable in bearing operation and choose the new permanent lubrication solution from Baart.

LUBRILIFE was tested against other permanent lubricants offered by 2 of our competitors.

We found that:

LUBRILIFE had the lowest oil loss over a 1700 hour test

LUBRILIFE has the most complete and consistent fill

LUBRILIFE utilizes both bearing seals; others operate with a single seal

Protects

Lubrilife fills the entire bearing cavity without impeding the rolling elements.

Seals

Lubrilife acts as an additional seal, in conjunction with the bearing seals.

For Life

Lubrilife provides oil for the life of the bearing. Never manually grease a bearing again.

A forethought, not an afterthought.

Lubrilife is a manufacturing step, not a modification.

Most competitor's solid lubrication is an aftermarket modification requiring permanent removal of a seal. The bearing (shown left) has had the remaining factory seal removed to show how an incomplete fill leaves rolling elements exposed. This creates drawbacks such as:

- faster oil loss with no method for relubrication,

- prone to damaging contamination,

- and washdowns jeopardizing the remaining seal’s integrity due to polymer voids.

In contrast, Lubrilife is applied before either seal is attached: a forethought, not an afterthought.

Make a greaseless bearing your permanent solution.

Is Mariner with Lubrilife right for your application? We've got some information we'd like to send you that will help you decide.

MARINER WITH LUBRILIFE

Frequently Asked Questions

Download a printable Lubrilife flyer and take it with you.

Download a pdf

The current bearings can operate in an ambient temperature range of -40°F to 195°F (the internal bearing temperature can be 265°). The lower temperature limit is limited by the oil, while the upper-temperature limit is limited by the polymer material.

Deep groove ball bearings can operate with a DN factor of 300,000.

DN = (bearing bore in mm + bearing OD in mm)/2 x (RPM)

The warranty is the same as other Baart products. One year materials and workmanship.

Mariner L4L with food-grade Lubrilife are available now, in limited shaft sizes and housing styles.

We are planning on having Turner L4L bearings available sometime in 2021.

The nomenclature has the suffix L4L (Lubricated for Life).

Lubrilife units will not have grease zerks on the housing, making them unable to be greased.

Lubrilife is available in both a standard industrial-grade base oil, as well as H1 compliant food-grade base oil, where incidental food contact is possible.

It is currently in development.

The standard oil is a full synthetic with additives. The food-grade oil is an H1 lubricant, where incidental food contact may potentially occur.

While permanent lubrication is superior to grease in excluding contaminants from the bearing, it performs best when used in conjunction with both bearing seals. Lubrilife ships with both factory seals applied post-process.

Learn more about calculating approximate life.